|

|

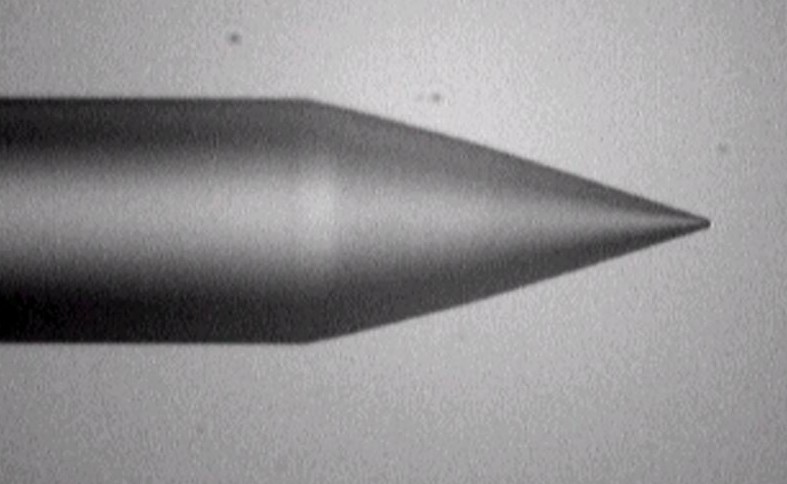

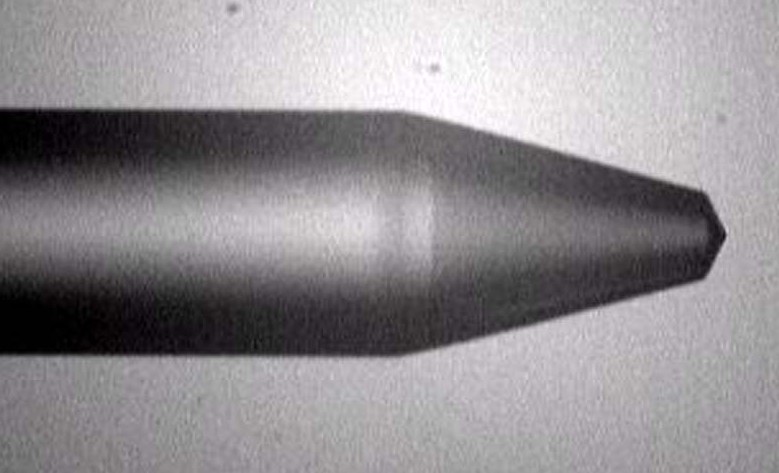

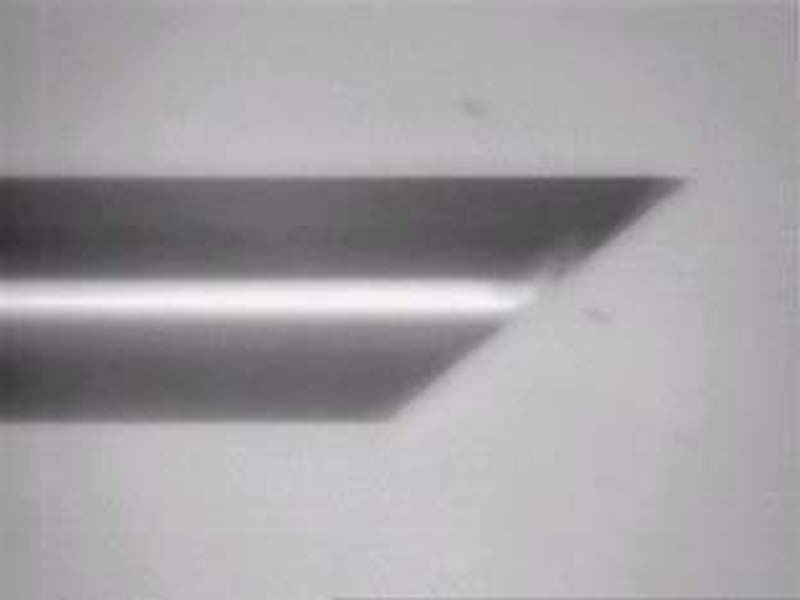

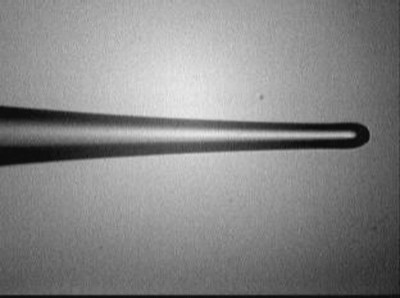

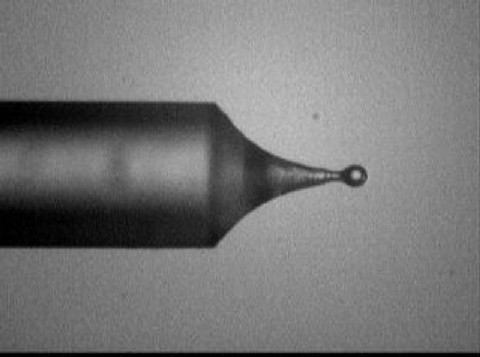

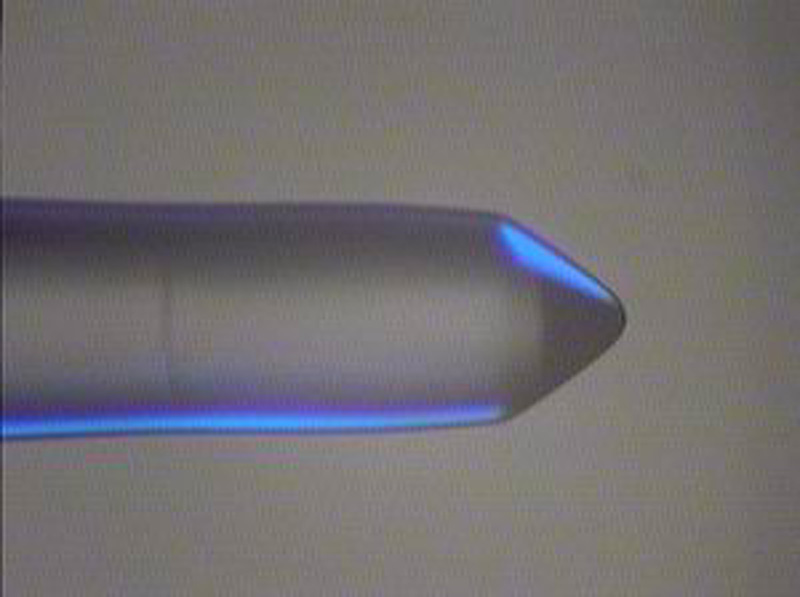

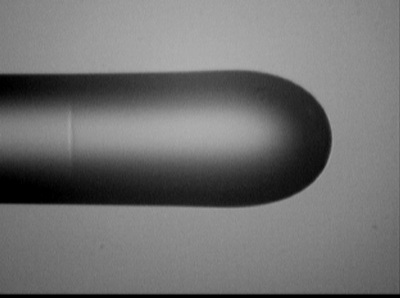

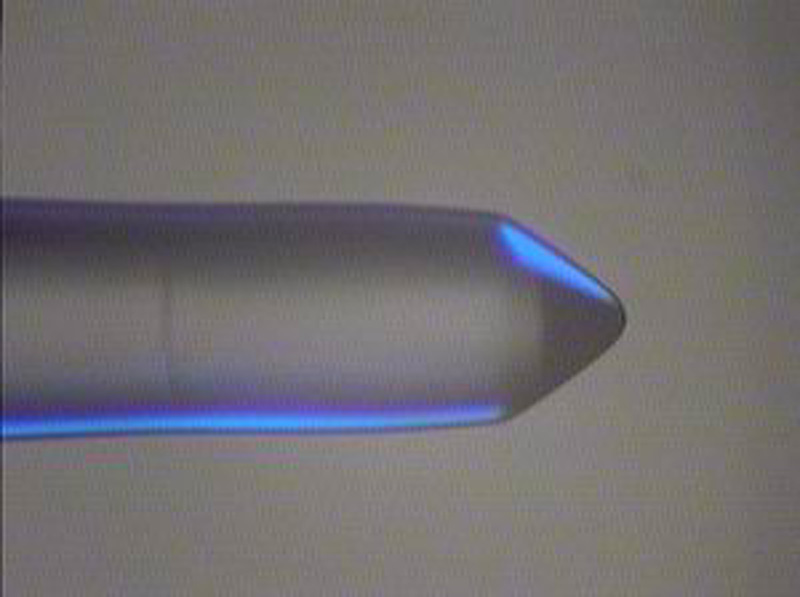

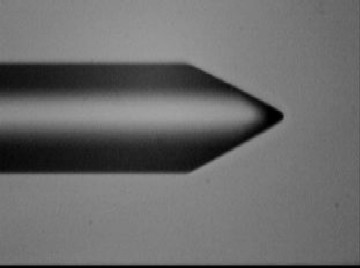

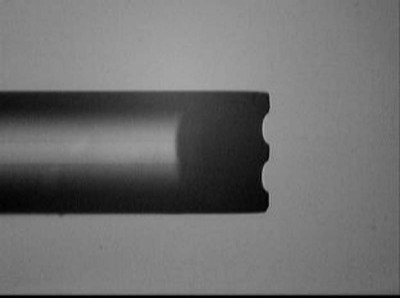

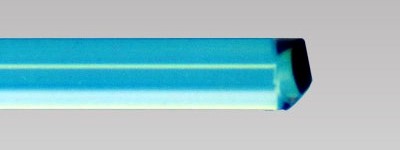

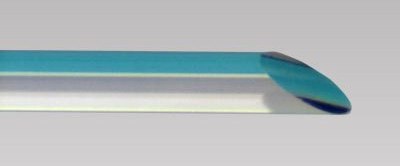

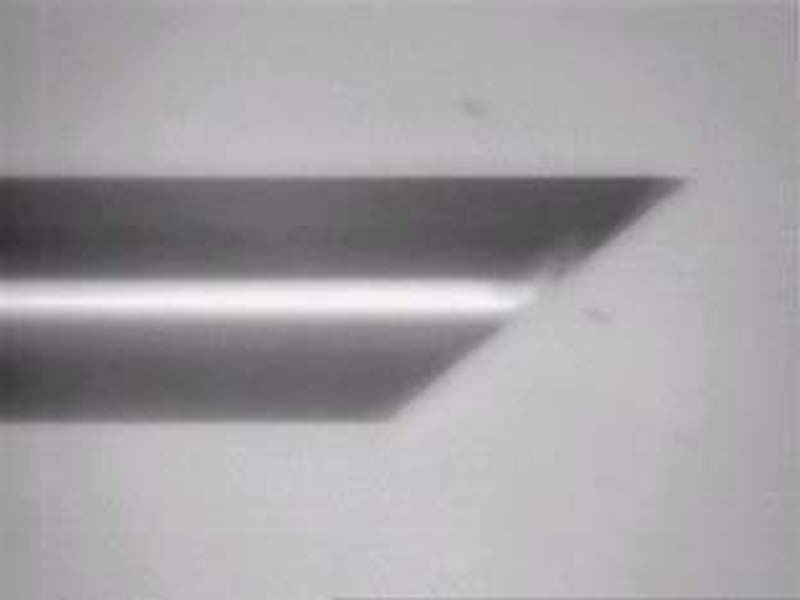

Lensed fibre , lensed fibre assembly, and fibre array are available in single mode, PM fibre, D-shape

fibre and multi mode fibre; in conical, wedge, angle and other customer tip shapes with/without AR coating

Various types of lensed fibres

|

|

|

|

|

|

|

|

|

|

|

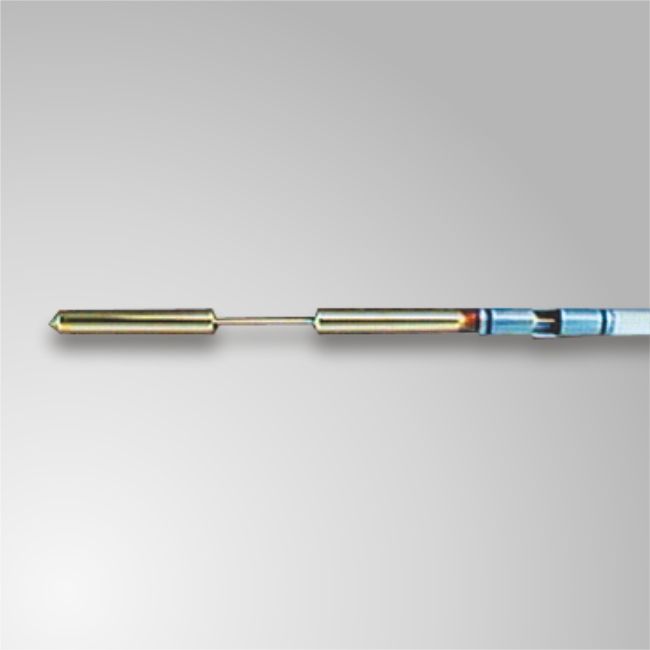

Double Ni Tube Fibre Assembly |

|

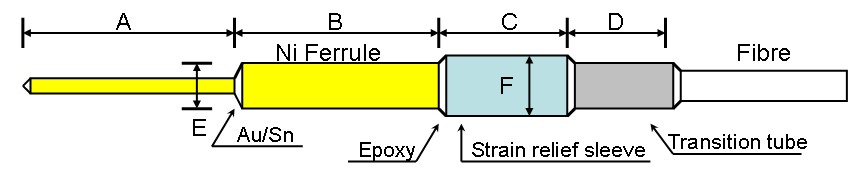

Single Ni Tube Fibre Assembly |

|

|

|

==================================================================================================================================

When communicate with us regarding the lensed

fibre, if possible, please provide following information:

-

Wavelength, type of fibre, single more or

multi-mode fibre? e.g. SFM-28,or PM1300, HI1060, etc.

-

Type of lens: conical, wedge/cylindrical

lens, or angled cylindrical lens, etc.

-

Radius or lens, or far-field angle, or spot size

-

Stripe length for lensed fibre, dimension of

fibre assembly

-

Total length, connector, AR coating?

-

Quantity

================================================================================================================================ |

|

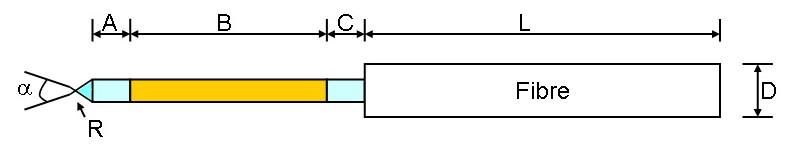

Parameter |

|

A |

bare

fibre length |

|

Lens type abbreviation:

- SLF:

Symmetrical Lensed (conical lens)

Fibre

- CLF:

Cylindrical Lensed Fibre

- ACLF:

Angle Cleaved Lensed Fibre

- BIC:

Biconical Lensed Fibre

- ABIC:

Angled Biconical Lensed Fibre

|

|

B |

metallised length |

|

C |

bare

fibre length |

|

D |

diameter of the fibre |

|

R |

radius of the lens |

|

a |

far-field angle |

|

θ |

cone

angle |

|

|

1.

Lensed Fibre /

Metalized Fibre

|

|

2. Long-focus Lensed Fibre / Metalized

Fibre:

Smaller spot size Longer working

distance High coupling efficiency

High quality Gaussian beam profile

|

|

θ |

30 - 33░(Std), 52~55░(Std)

110 - 120░(Std) or customer require (30 -120░) ▒ 2░ |

|

R |

7 - 8Ám (Std) or customer require▒1Ám |

|

MFD |

3.0 ▒ 0.5μm or > 2.5μm |

|

Working distance |

≥

18μm |

|

Return loss |

> 40dB |

|

A

|

0.2-0.4mm (Std), or customer require ▒ 0.2mm

|

|

B

|

Customer require▒0.5mm

|

|

C

|

0mm(Std), or customer require ▒ 0.5mm

|

|

L

|

Customer require+0.5m

|

|

Nickel plating thickness

|

2 -3Ám (Std) 1 - 10Ám(customer require)

|

|

Gold plating thickness

|

0.1 - 0.2Ám

|

|

Metal coating pull strength

|

> 10N

|

|

Operating temperature

|

-40 - +85C

|

|

Soldering temperature

|

280 - 300C

|

|

Recommended solder

|

80%Au/20%Sn

|

|

Fibre end coating

|

Customer require, AR Coating

|

|

Connector type

|

Customer require

|

|

|

|

|

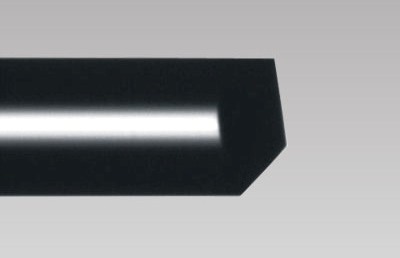

3.

Cylindrical

Lensed/Wedged Fibre

|

θ

|

50-55░ (Std)

112 ▒ 2░ or customer size (50 - 90░) ▒ 2░

|

|

|

|

R

|

4-5Ám (Std) or Customer require ▒ 1Ám

|

|

A

|

0.2 - 0.4mm (Std), or customer require ▒ 0.2mm

|

|

B

|

Customer

require▒0.5mm

|

|

C

|

0mm(Std), or customer require▒0.5mm

|

|

Nickel

plating thickness

|

2 -3Ám (Std) 1 -10Ám(Customer require)

|

|

|

|

Gold

plating thickness

|

0.1-0.2Ám

|

|

Metal

coating pull strength

|

>10N

|

|

Operating temperature

|

-40-+85C

|

|

Soldering temperature

|

280-300C 80%Au/20%Sn

|

|

Fibre

end coating

|

Customer

require, AR Coating

|

|

Connector type

|

Customer

require

|

4.

Angle

Polished Fibre (0~10░ or 30 - 50░)

|

|

θ

|

8 ▒ 1░(Std), or customer size(0 ~ 10░) ▒ 1░

37/45 ▒ 1░(Std), or customer size(30 ~ 50░) ▒ 1░

|

|

A

|

0.2 ~ 0.4mm(Std), or customer require ▒ 0.2mm

|

|

B

|

Customer

require▒0.5mm

|

|

C

|

0mm(Std), or customer require▒0.5mm

|

|

Nickel

plating thickness

|

2~3Ám(Std) 1~10Ám(customer require)

|

|

Gold

plating thickness

|

0.1 ~ 0.2Ám

|

|

Metal

coating pull strength

|

> 10N

|

|

Operating temperature

|

-40 ~

+85 C

|

|

soldering temperature

|

280 ~

300 C

|

|

Recommended solder

|

80%Au/20%Sn

|

|

|

|

5.

Fibre

Assembly for packaging

|

Lens-ended

Fibre |

Tapered

Polished, Wedged Cylindrical, Angle Polished, Fused

Tapered Lens-ended Fibre |

|

Helium

leak rate |

< 1 Î 10-8 atm cc/Sec. He |

|

Nickel

plating thickness |

2~3Ám

(Std) or 1~10Ám (customer require) |

|

Gold

plating thickness |

0.1 ~ 0.2Ám |

|

Fibre pull

strength |

> 10N

|

|

Metal

coating pull strength |

> 10N

|

|

Operating

temperature |

-40

- +85c |

|

Soldering temperature |

Under 250c |

Single Ni Tube Fibre Assembly

|

|

|

A |

Customer size ▒ 0.5mm |

|

B |

Customer size ▒ 0.5mm |

|

C |

5.8 ▒ 0.2mm (Std) |

|

D |

Customer size▒1mm (for 250um fibre) |

|

E |

0.85 ▒ 0.02mm (Std) |

|

F |

1.3 ▒ 0.05mm (Std) |

|

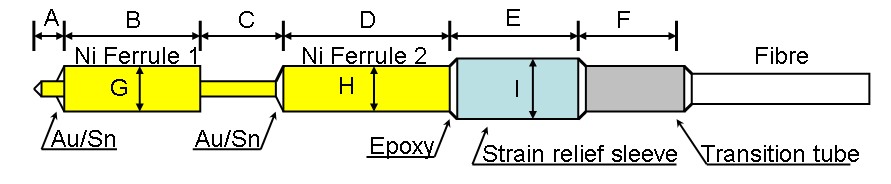

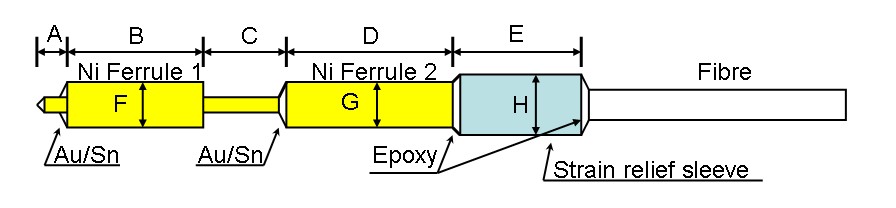

Two Ni Tube Fibre Assembly

|

|

|

A |

0.3~0.4mm (Std) or customer size ▒ 0.1mm |

|

B |

6mm

(Std) |

|

C |

Customer size ▒ 0.5mm |

|

D |

7/11 ▒ 0.5mm (Std) |

|

E |

5.8 ▒ 0.2mm (Std) |

|

F |

Customer size ▒1mm (for 250um fibre) |

|

G |

0.85 ▒ 0.02mm (Std) |

|

H |

0.85 ▒ 0.02mm (Std) |

|

I |

1.3 ▒ 0.05mm (Std) |

|

|

Mini Two

Ni Tube Fibre Assembly for 14-pin DIL or Butterfly LD

Package |

|

|

A |

0.3~0.4mm (Std) or customer size ▒0.1mm |

|

B |

4mm

(Std) |

|

C |

Customer size ▒0.5mm |

|

D |

4 ▒ 0.5mm (Std) |

|

E |

5 ▒ 0.2mm (Std) |

|

F |

0.85 ▒ 0.02mm (Std) |

|

G |

0.85 ▒ 0.02mm (Std) |

|

H |

1.3 ▒ 0.05mm (Std) |

|

|

|

|